The Preservation Project: Progress Towards Perfection

It’s been five months since we introduced you to Matt and Amy McDonald and their Olde Towne Daphne dream-house-turned-nightmare due to termite infestation. At the time, brothers Jared and Geoffrey Cochran, co-owners of Cochran Builders, Inc., were working with their top-notch team to restore this pre-Civil War gem to its original glory, guided by prominent architect L. Craig Roberts. To say they’ve come a long way is an understatement.

By Amber Wielkens Photos Layla Lambert, L-egantPortraits.com

Let’s start with a short recap of what we learned last May. In 2015, Matt and Amy McDonald bought the bayfront Cullum-Lee-Caffey home, a Gulf Coast Greek Revival cottage listed on the National Register of Historic Places. Three years later, termites had destroyed it. With different owners, the home might have been torn down and a new one built, but Amy and Matt were utterly committed to restoring their home to its original state. Hiring a dream team of the area’s best in architecture, building, woodwork, and more, the house was taken apart down to the studs and every historical detail replicated using expert craftsmanship and the same hand tools used by the original builders 175 years ago. This painstaking labor of love was undertaken with enthusiasm by builders Jared and Geoffrey Cochran, whose first and foremost task was ensuring all the termites and damaged wood were removed.

Fast-forward to the present, and we’re awestruck at the progress they’ve made. No longer a sea of studs marking the outline of what were once rooms, the interior boasts completed walls; temporary flooring is being replaced with golden antique heart pine; moldings and trim are being added, and the exterior is being prepped to be painted. Color us amazed at the transformation being wrought by these masters of their crafts.

“At this point we’re in various stages of the ‘finishing’ process,” Jared says, adding, “Since Access last visited the site in May, we’ve made tremendous progress on the interior. First, we insulated the entire home with open cell spray foam, which provides the greatest value of all the forms of insulation, then we hung sheetrock and have since finished all of it. Our finish carpenters have been installing trim materials and working in concert with the hardwood flooring installers.” Like conductors of an orchestra, it’s their job to ensure their team and the other contractors on-site are keeping perfect time together so that none is wasted. Geoffrey adds, “We’ve also begun sanding and prepping the exterior of the house so we can start the paint process.”

No strangers to big builds, Jared and Geoffrey still love the challenge of overseeing a project where an entire house is taken apart and rebuilt to exacting historical detail. As always, they’re the first to ensure credit is given to both their team at Cochran Builders and the elite subcontractors working with them.

Geoffrey shares, “Greg Maddox with Maddox Custom Cabinets & Millworks Inc. has begun the tedious process of building all the furniture-grade cabinetry throughout the house at his shop off-site. We salvaged as much of the original hardwood flooring as we could when our team was in the demolition process. All that wood was then shipped to Deas Millwork to be de-nailed and then reprocessed so we could put it back in the home.”

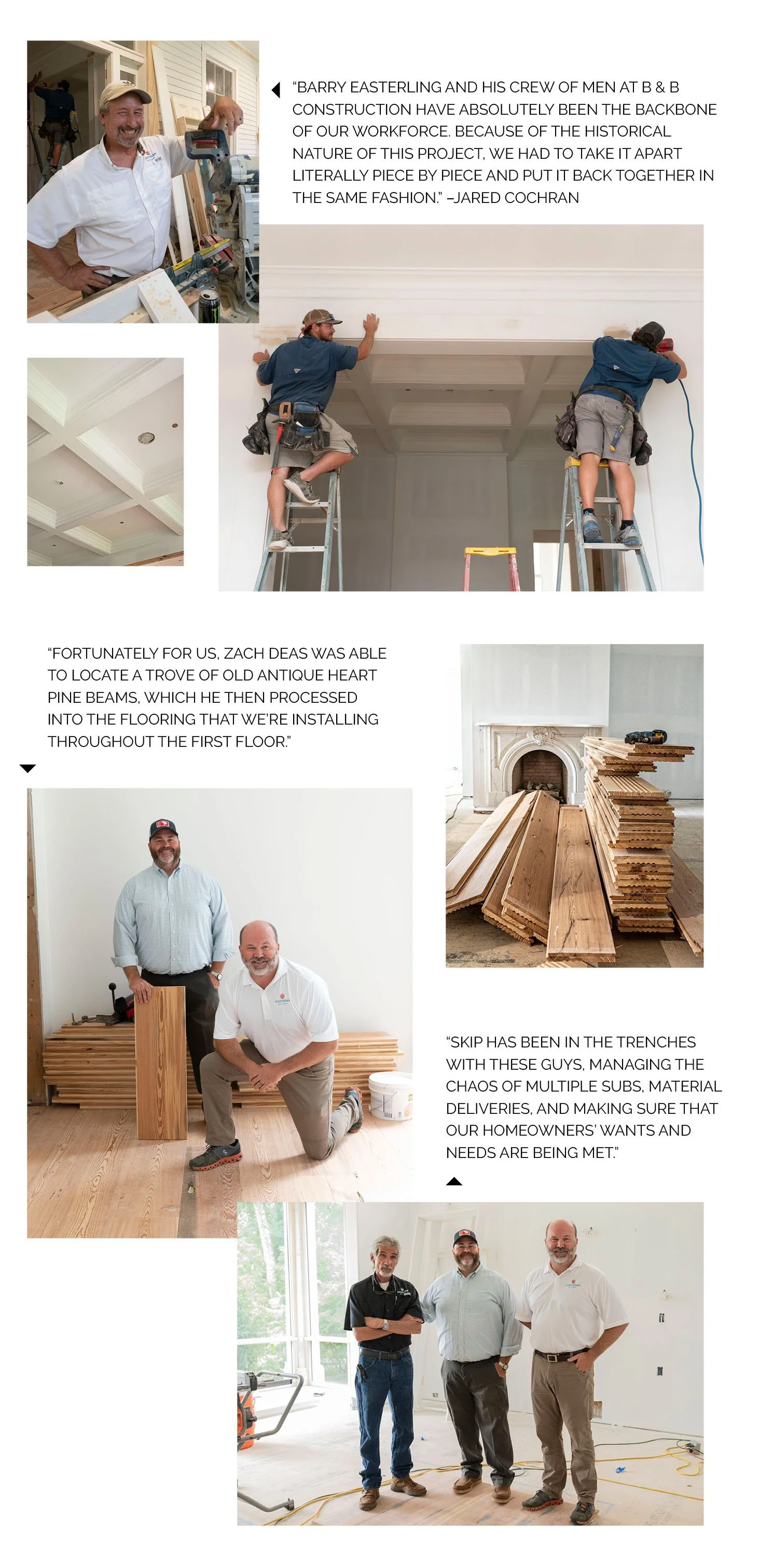

Since so much of the original floor was damaged by termites, they were only able to salvage enough for the floors upstairs. Jared adds, “Fortunately for us, Zach Deas was able to locate a trove of old antique heart pine beams, which he then processed into the flooring that we’re installing throughout the first floor. Finding such materials is not an easy task and we really appreciate the efforts Zach made for us to keep the historical nature of this process alive.”

More praise for Deas Millwork comes from Geoffrey, who claims, “The moldings in this home aren’t something we could purchase at any local building supply store. Luckily for us, Deas was able to come through again. We saved pieces of the old moldings and Zach actually made the knives to cut new material to match the original. Jared and I knew when we took on this project the importance of having a company like Deas Millwork. Their contribution to this restoration has been massive and we could not have accomplished it without the unique machinery and talented people working there.”

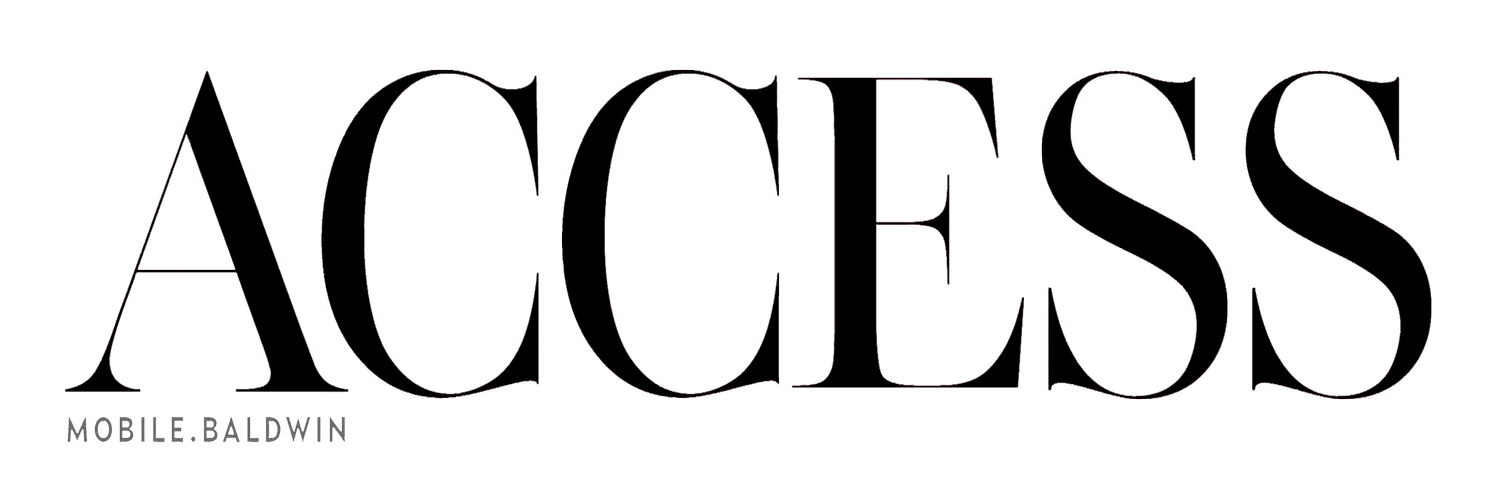

Deep appreciation is also extended to those who have been on the project since day one. Jared declares, “Barry Easterling and his crew of men at B & B Construction have absolutely been the backbone of our workforce. Because of the historical nature of this project, we had to take it apart literally piece by piece and put it back together in the same fashion. This is wearisome and sometimes backbreaking work. Barry and his men understood the importance of this project and have executed this task flawlessly without a single complaint—a rare quality these days!”

Calling project manager Skip Jones their ringmaster, Geoffrey says of him, “Skip has been in the trenches with these guys, managing the chaos of multiple subs, material deliveries, and making sure that our homeowners wants and needs are being met. It truly takes a team of craftsmen to pull off a project like this, and all these gentlemen are exactly that!”

Spending their summer battling excessive heat and unprecedented amounts of rain, the crew also had to deal with supply chain issues that, since the pandemic, have become a become a daily problem for all of us. Nonetheless, Jared claims, “Our timeline is to have the McDonalds back in their home by Thanksgiving; I think that is very doable.” Home for Thanksgiving sounds good to us.

Wrapping up, Geoffrey has a few final thoughts, telling us, “Projects like this are not common. In fact, they’re very rare. This has been the most challenging endeavor our company has engaged in by far. We are blessed to have such a wonderful team of talented men and women who have risen to the occasion and exceeded every expectation we had for them.” Jared concludes, “It’s also important we mention our gratitude for homeowners like the McDonalds, who understood the immense challenge we faced and trusted us to make this happen. Matt and Amy McDonald have been outstanding clients and have fueled this project not only financially, but with the confidence they have placed in us. It’s easy to work for people who trust you and your team—that’s why this project is going to be a huge success!” See you at Thanksgiving!

Cochran Builders, Inc. | 251.423.9686 | CochranBuildersInc.com | @CochranBuilders